+86-13077884120

+86-13077884120 +86-13266789839

+86-13266789839

MFG@trendy-sz.com.cn

MFG@trendy-sz.com.cn 86+13077884120

86+13077884120 gxm1235201

gxm1235201 1796474535

1796474535

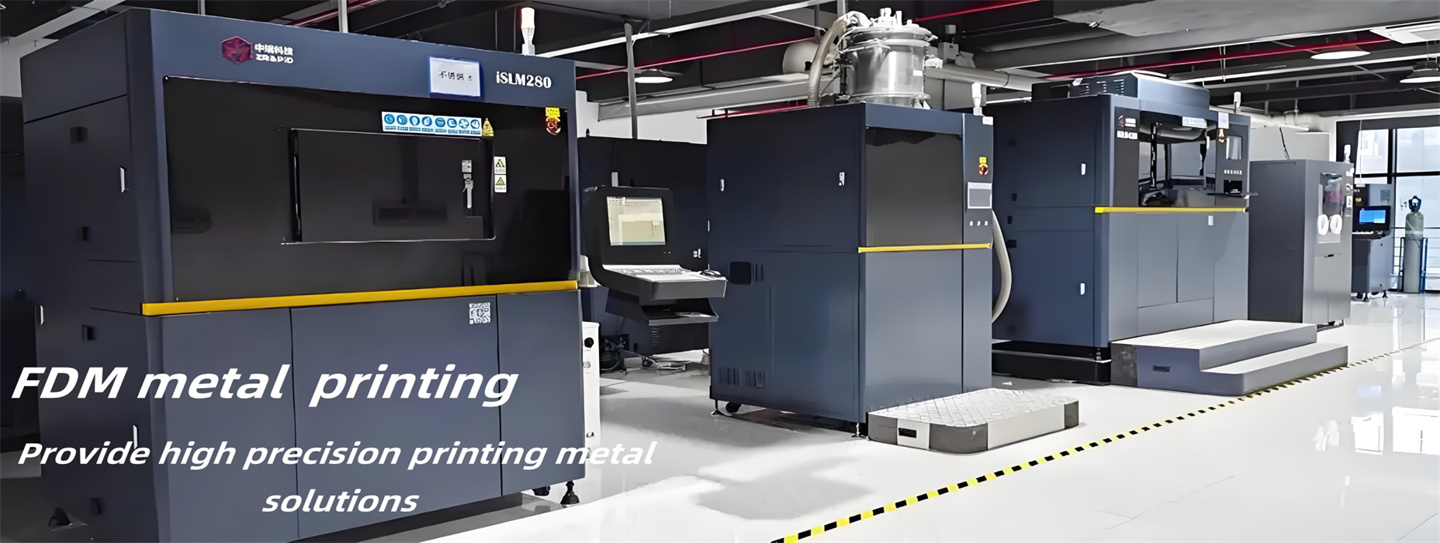

Metal 3D Printing with FDM/SLMS /DLMS

FDM /SLMS Metal Materials printing Available at Trendy Direct Metal Laser Sintering (DMLS) is an advanced metal 3D printing process for rapid prototyping and production of fully functional metal parts….

FDM /SLMS Metal Materials printing Available at Trendy

Direct Metal Laser Sintering (DMLS) is an advanced metal 3D printing process for rapid prototyping and production of fully functional metal parts. With DMLS, metal prototypes can be created and final parts produced within 7 days. The technology supports a wide range of metals and can produce parts suitable for end use. DMLS are commonly used for prototyping using production-grade materials, manufacturing complex geometry, producing functional end parts, and reducing the number of metal parts in a component.

What We can provide range material in Trendy.

| Material of type | Stain Steel | Stain Steel | Mold steel | TC4TAI | AU4G | Aluminum | Nickel base high temperature alloy | |

| Printing Material | 316L | 17-4PH | 18NI300 | TC4 | AlSi10Mg | 6061 | GH4169 | |

| Performance table | Grain size | 15-53μm | 15-53μm | 15-53μm | 15-53μm | 15-53μm | 15-53μm | 15-53μm |

| Shape | ball | ball | ball | ball | ball | ball | ball | |

| Mobility | 40S | 22S | 40S | 45S | 150S | 120S | 45S | |

| Apparent density | 3.9g/cm³ | 4.0g/cm³ | 4.3g/cm³ | 2.5g/cm³ | 1.45g/cm³ | 1.07g/cm³ | 4.4g/cm³ | |

| Performance table | Density | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥98% | ≥99% |

| Strength of extension | ≥560Mpa | ≥1100Mpa | ≥1090Mpa | ≥600Mpa | ≥330Mpa | ≥280Mpa | ≥980Mpa | |

| Hardness | 11-12HRC | 13-16HRC | 30-36HRC | 30-35HRC | 60-75HB | 90-95HB | 283HB | |

| Yield strength | ≥560Mpa | ≥1050Mpa | ≥1000Mpa | ≥540Mpa | ≥245Mpa | ≥230Mpa | ≥700Mpa | |

| Ductility | ≥25Mpa | ≥15Mpa | ≥10Mpa | ≥5Mpa | ≥6Mpa | ≥8Mpa | ≥13Mpa | |

| Heat treatment properties | Strength of extension | ≥560MPa | ≥1250Mpa | ≥1930Mpa | ≥1150Mpa | ≥310MPa | ≥290mpa | ≥1450Mpa |

| Yield strength | ≥400MPa | ≥1150Mpa | ≥1890Mpa | ≥1200Mpa | ≥200MPa | ≥250Mpa | ≥1000Mpa | |

| Hardness | 13-15HRC | 32-42HRC | 48-52HRC | 35-40HRC | 90-120HB | 95-120HB | 455HB | |

| Extend rate | ≥32Mpa | ≥20Mpa | ≥4Mpa | ≥12Mpa | ≥8Mpa | ≥14Mpa | ≥20Mpa | |

| Elasticity modulus | 180Gpa | 200Gpa | 160GPa | 100-120GPa | 70GPa | 70GPa | 140-180GPa | |

| Coefficient of thermal expansion | 68-212˚F,/ ˚F: 6.0 x 10 -6 | 11.2×10-6 | ||||||

| Poisson’s ratio | 0.25-0.3 | 0.32-0.36 | ||||||

| Thermal conductivity | w/(m.k)100℃-: 17.2 w/(m.k)500℃-: 23 |

25-30W (M.K) | ||||||

| Electrical resistivity | Microhm-in: 38.6 | |||||||

| Electric conductivity | 1.4-1.5 * 106 S / m | |||||||

| Fusing point | 1450℃ | 1500℃ | 1350℃ | 1700℃ | 700℃ | 700℃ | 1300℃ | |

| Operating temperature | 650℃ | 700℃ | 800℃ | 900℃ | 350℃ | 350℃ | 800℃ | |

| Roughness of molded parts | RA6.3-7 | |||||||

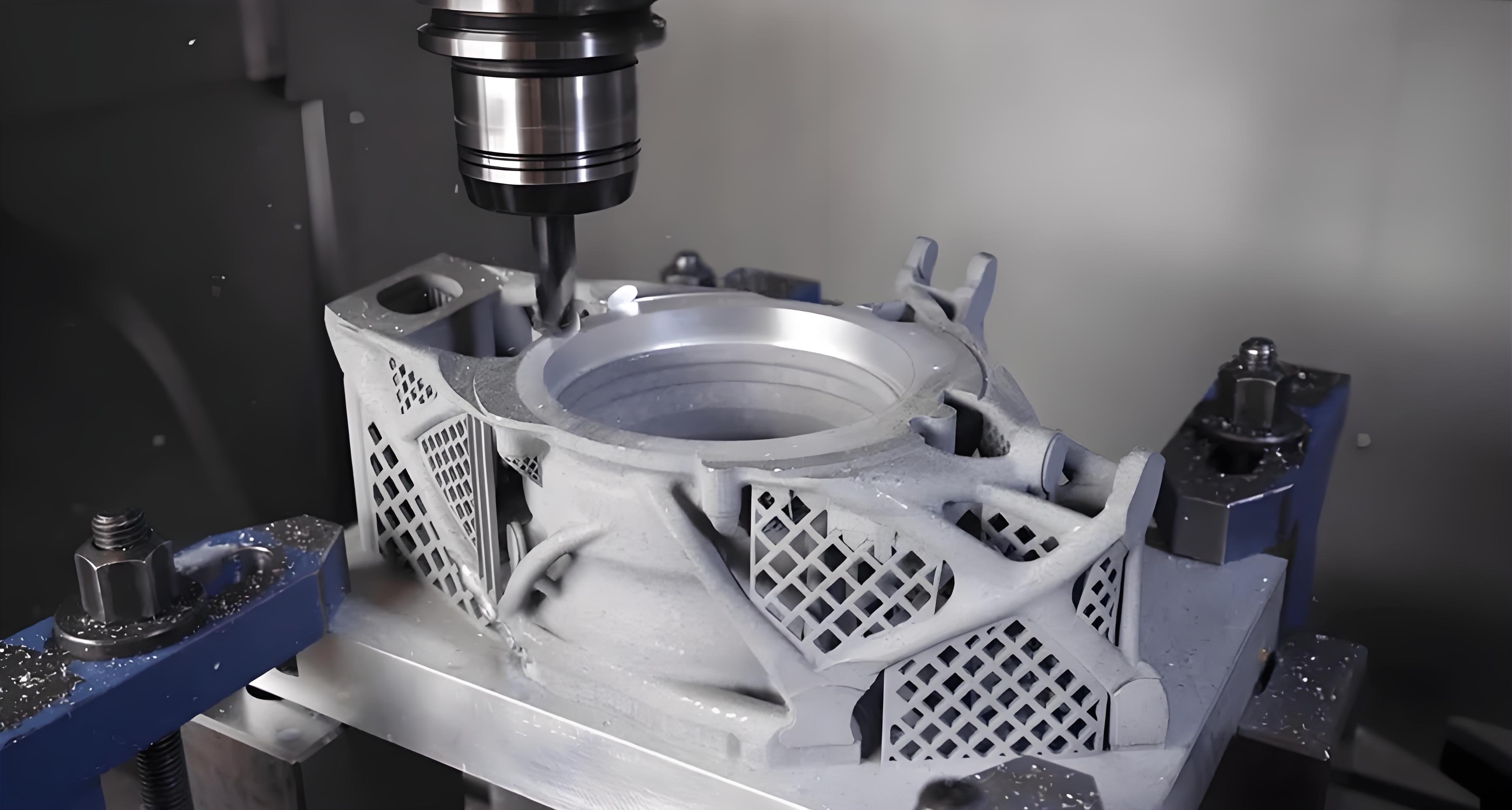

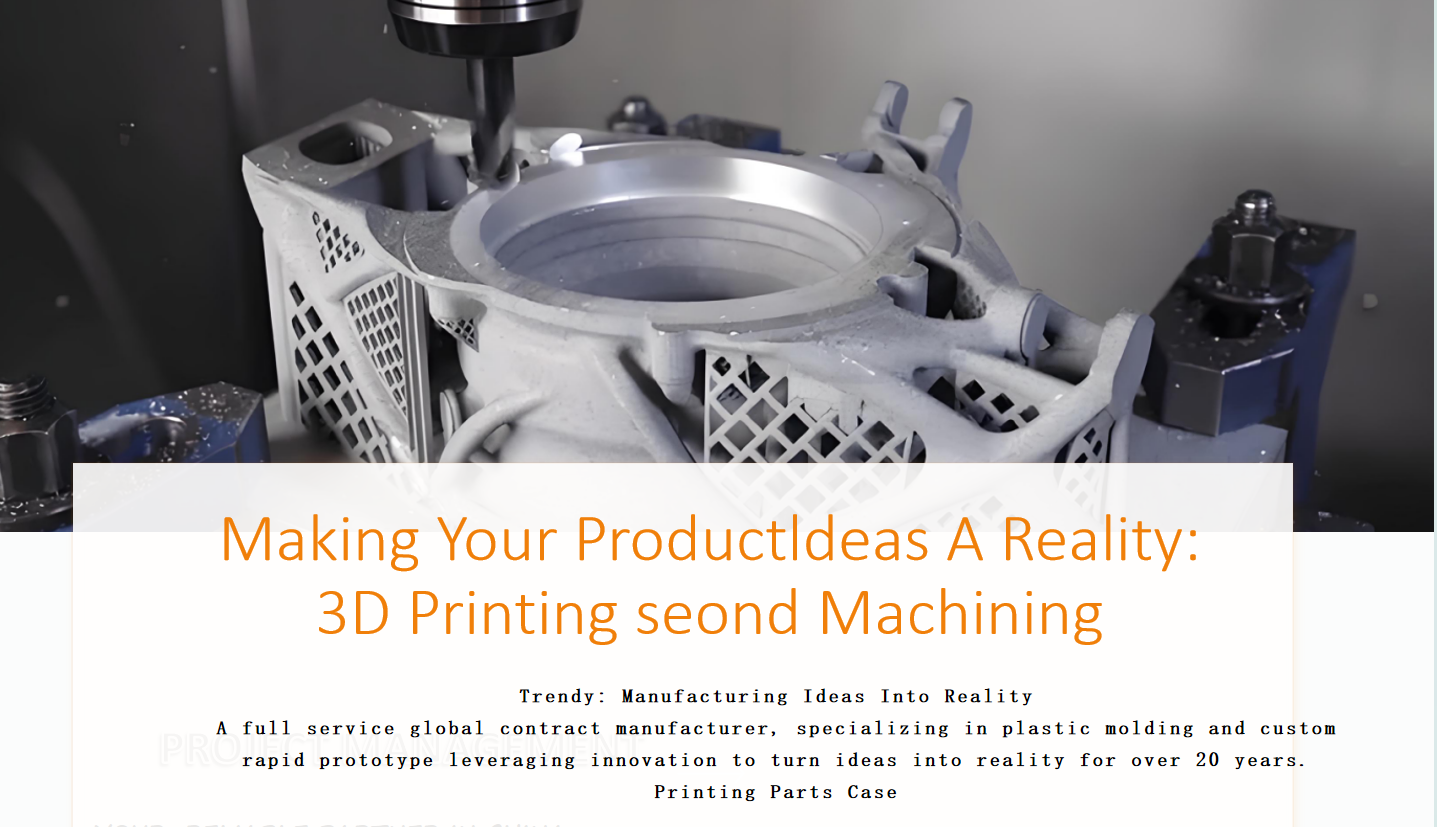

When performing secondary CNC machining on 3D printed metal materials, key focuses should be placed on three dimensions: process planning, material properties, and machining operations:

I. Process Planning

Plan the machining allowance accurately based on the forming accuracy of 3D printed parts, CNC machining processes, and part structural characteristics. For example, thin-walled parts require a balance in allowance to avoid deformation caused by excessive allowance or failure to eliminate printing defects due to insufficient allowance. High-precision parts like shafts should reserve uniform allowance in the diameter direction to ensure subsequent machining accuracy.

2. Tolerance Coordination Control

Clarify the tolerance ranges of 3D printing and CNC machining, and use the tolerance allocation method to reasonably decompose the total tolerance into each machining link. Strictly control the cumulative tolerance effect to prevent parts from being scrapped due to error superposition.

3. Microstructure Adaptability

The rapid solidification process of 3D printing easily generates special structures such as columnar crystals and residual stress. Evaluate their impact on cutting performance, and optimize the material’s metallographic structure through heat treatment to improve machinability.

4. Residual Stress Management

Residual stress from printing may cause part deformation under cutting forces. It is recommended to eliminate stress through stress-relief annealing pretreatment, or adopt strategies like step-by-step machining and symmetric cutting in process design to reduce deformation risks.

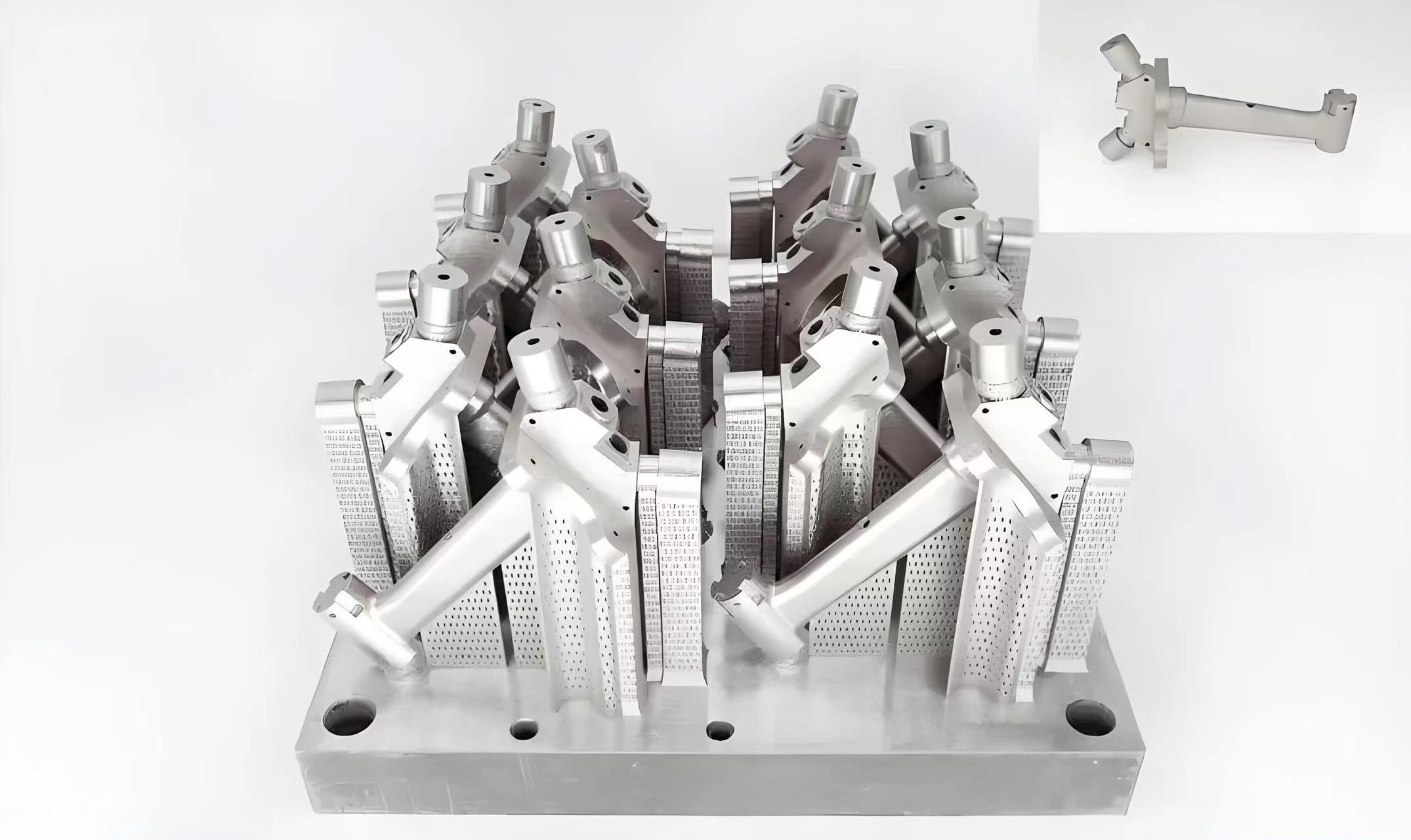

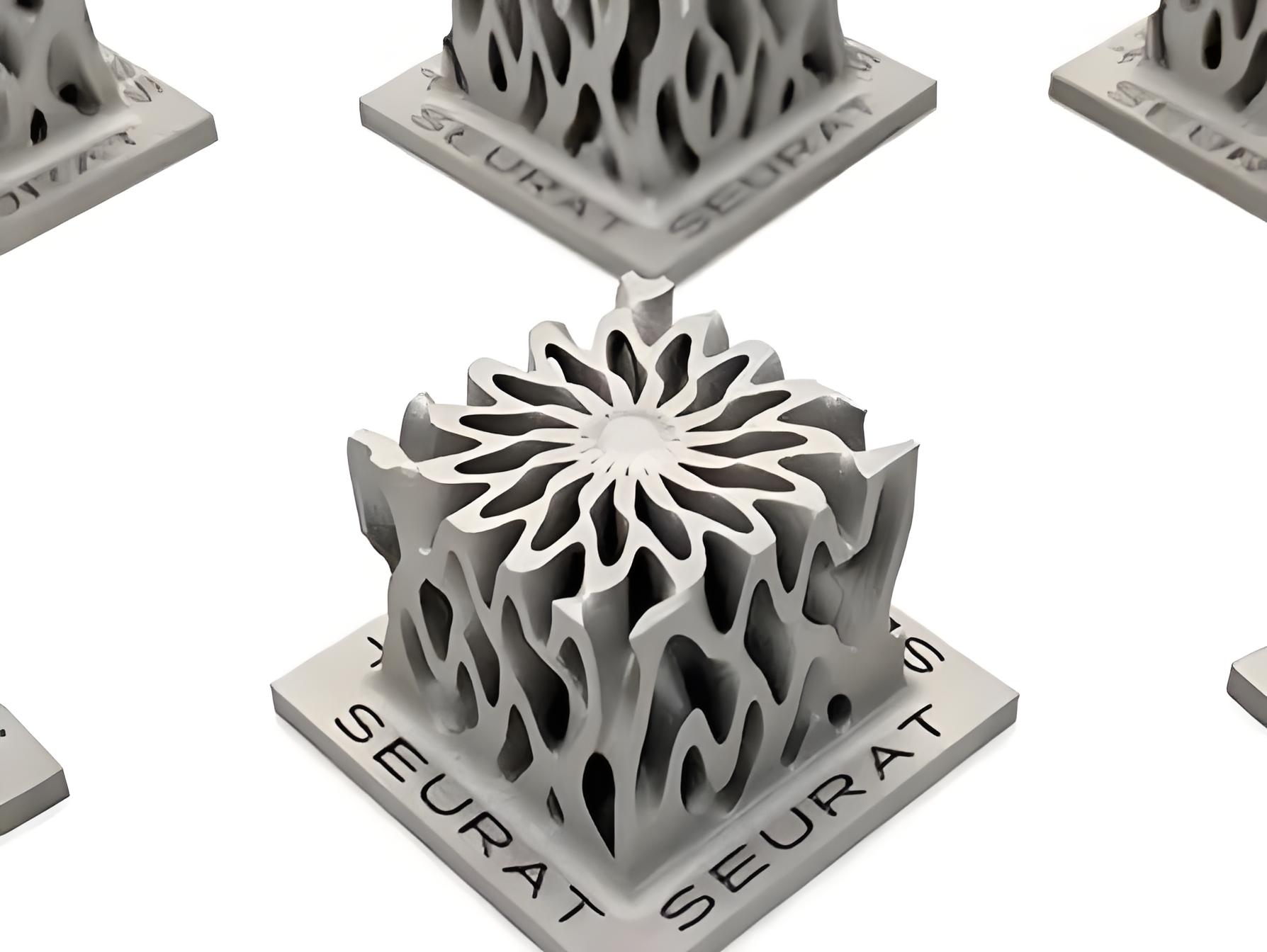

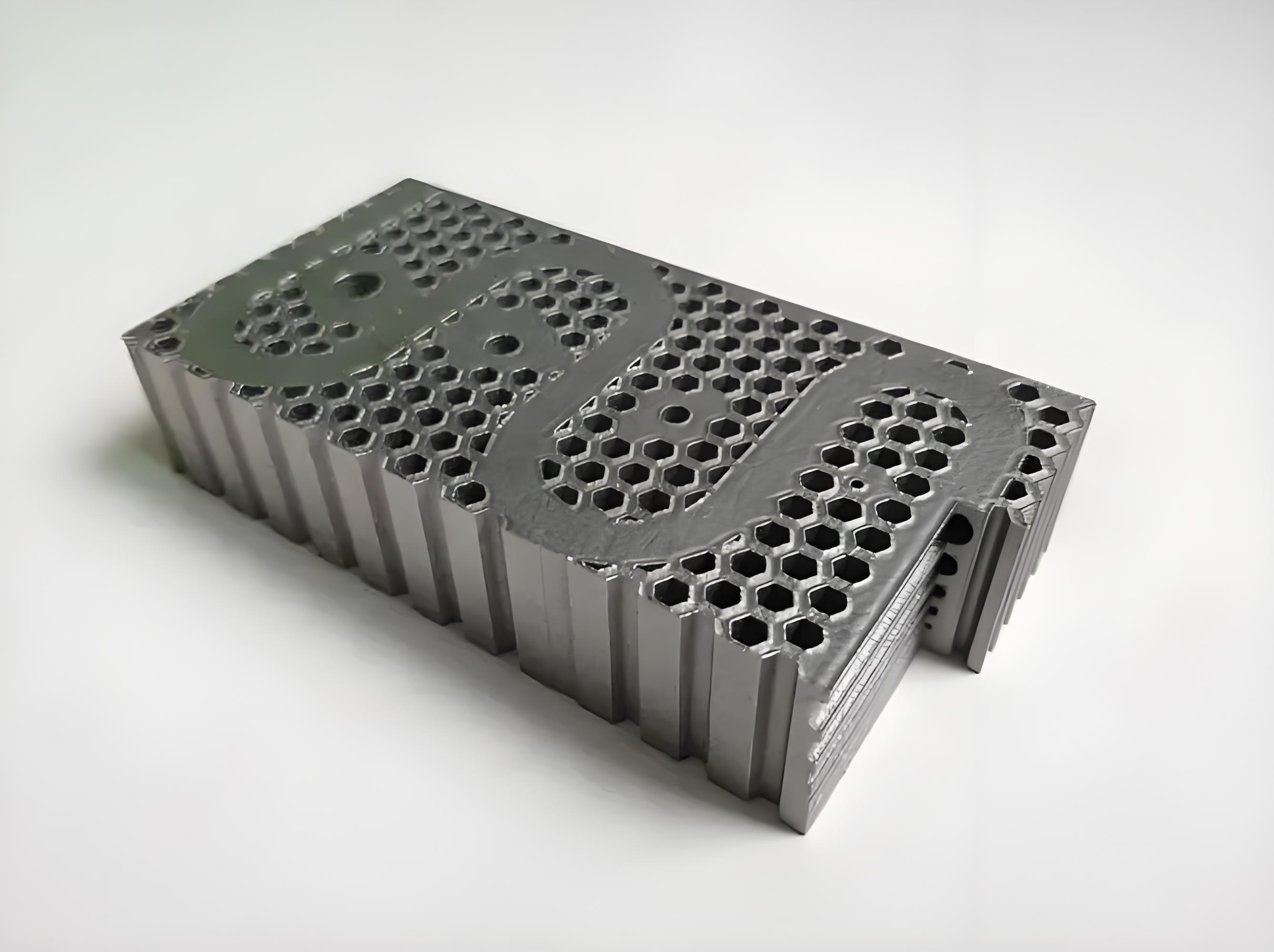

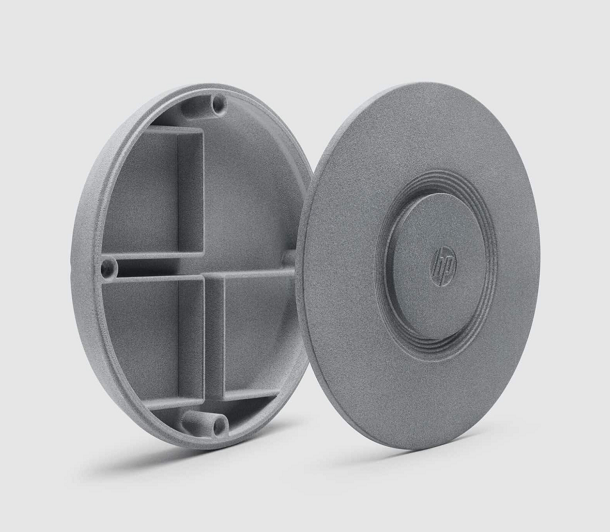

Printing Parts Case

|

|

|

Which’s Available post processing for Finishes?

|

3-axis, 5-axis milling; Turning; Polishing (mirror or brushed); Passivation; Wire cutting processing; Tapping, reaming; Heat treatment Relieve stress; NADCAP heat treatment electroplate |

|

Hot isostatic pressing (HIP) Solution annealing Aging; Mechanical test stretch Rockwell hardness Powder Analysis & Material Traceable analyzer Chemistry Particle size and distribution analysis |

Why choose Metal Printing

1. Can manufacture complex parts: Metal printing can produce very complex metal parts, which are usually difficult to manufacture through traditional metal processing methods. This makes metal printing ideal for manufacturing high-precision, high-complexity parts.

2. Can manufacture parts quickly: Metal printing can produce parts in a short time, which makes it ideal for rapid prototyping and small batch production. Compared with traditional metal processing methods, metal printing can save a lot of time and cost.

3. Can reduce waste: Metal printing can reduce waste, because it can directly convert metal powder into parts, without the need for a lot of cutting and processing as traditional metal processing methods. This makes metal printing an environmentally friendly manufacturing technology.

4. Can improve production efficiency: Metal printing can improve production efficiency because it can manufacture multiple parts at the same time. This makes metal printing an efficient manufacturing technique.

How to choose 3D printing method?

|

|

| FDM Functional prototyping and small batch production The dimensional accuracy is ± 0.3%, and the lower limit is ± 0.3mm |

SLM/DMLS/SLMS High precision metal fabrication Dimensional accuracy ±0.1%, lower limit: ± 0.1mm Suitable for complex and detailed metal parts Delivery time is 2-3 working days |

Hot Tags: metal 3d printing with fdm/slms /dlms, China, manufacturers, factory, customized, wholesale, buy