+86-13077884120

+86-13077884120 +86-13266789839

+86-13266789839

MFG@trendy-sz.com.cn

MFG@trendy-sz.com.cn 86+13077884120

86+13077884120 gxm1235201

gxm1235201 1796474535

1796474535

Mold sevices

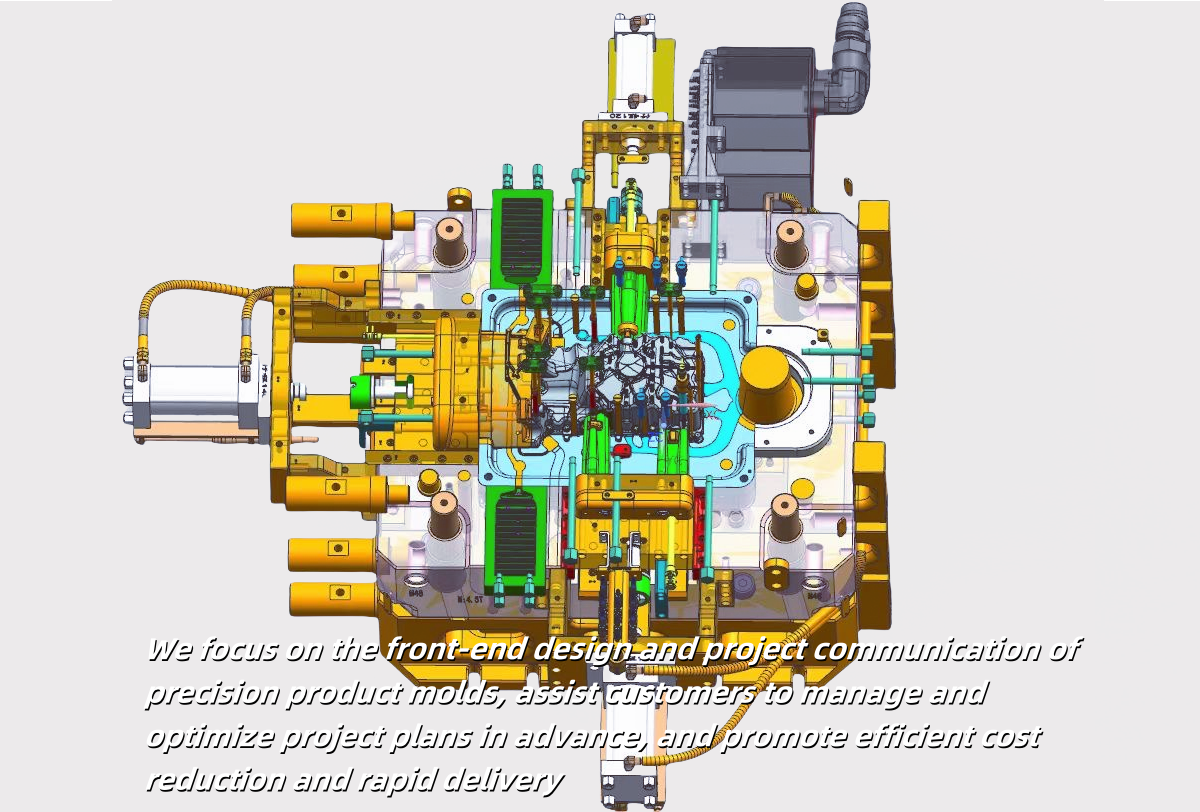

What is Plastic Injection Mould Design? Free DFM for Excellent Results Trendy a leader in the plastic injection mould industry, we know that a quality part comes from…

What is Plastic Injection Mould Design?

Free DFM for Excellent Results

Trendy a leader in the plastic injection mould industry, we know that a quality part comes from a quality mould and a good part design. Comprehensive mould design is the key to getting a high-performance mould.

our team has established the European mold market service, can provide a full 24 hours after-sales service, covering the business including mold manufacturing, mold repair, injection molding, mold accessories customization, etc., we focus on every customer’s service experience!

Continuous innovation management, efficient optimization of quality and cost reduction for each production is our advantage of customer product mold project management!

Trendy Mould Is Able To Design Mould According To Customer’S Product Designs, 2d/3d Models, Or Drawings With Specifications. Our Design

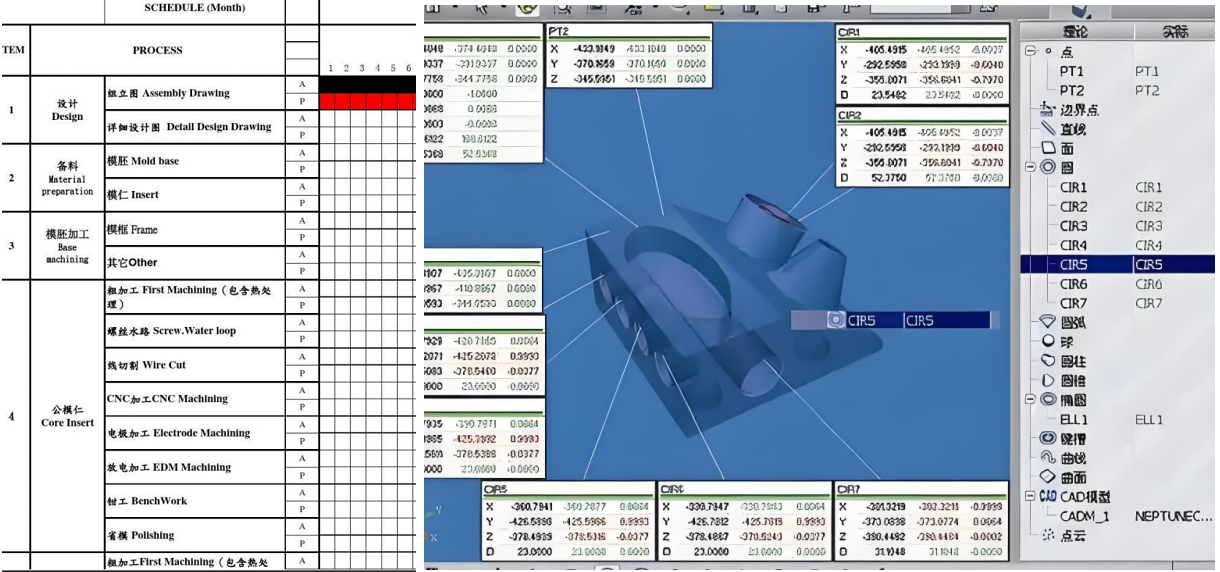

With more than a decade of experience combined in the molding and plastics industry, we are able to anticipate potential quality and tool manufacturing problems or risks at the earliest stage and optimize the design with the customer to eliminate those risks before the start of mould production.

Capability Includes:

DFM

Mould flow analysis

Product optimization

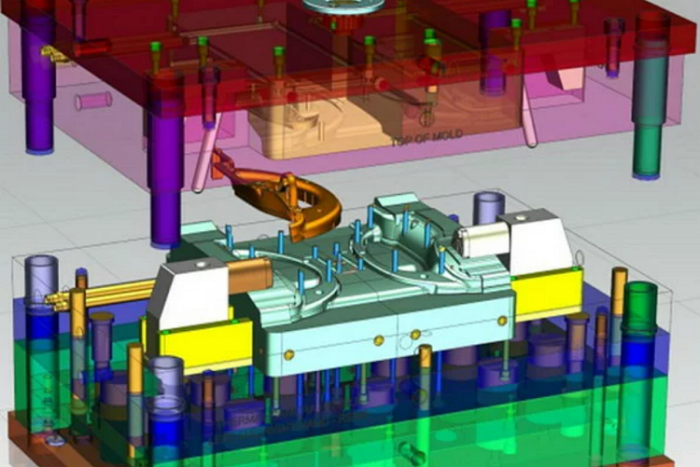

Full 2D & 3D mould design

Reverse engineering

Unique designs through collaboration with customers

We design our moulds based on customer input and mould complexity.

We design our moulds based on customer input and mould complexity.

With more than a decade of experience combined in the molding and plastics industry, we are able to anticipate potential quality and tool manufacturing problems or risks at the earliest stage and optimize the design with the customer to eliminate those risks before the start of mould production.

The Engineering Software Used At Trendy:

• Mould design software: AutoCAD, UG

• Programming software: Powermill

• Data exchange: UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, DXF, PDF, etc.

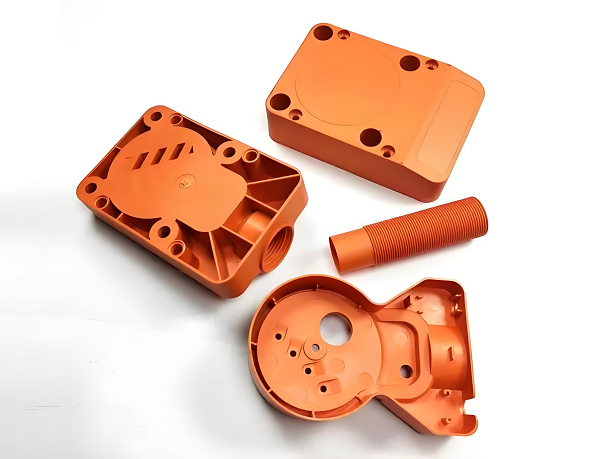

What We can provide range material at Trendy.

The injection of materials such as ABS, PMMA, PC, PA, POM, TPE. PP. PA+30%GF etc. This technique also offers the possibility of plastic over molding (e.g., shore on ABS), over molding of inserts and a wide choice of finishes. The physical, mechanical, thermal and aesthetic qualities of the parts created are very similar to those of serial injection parts.

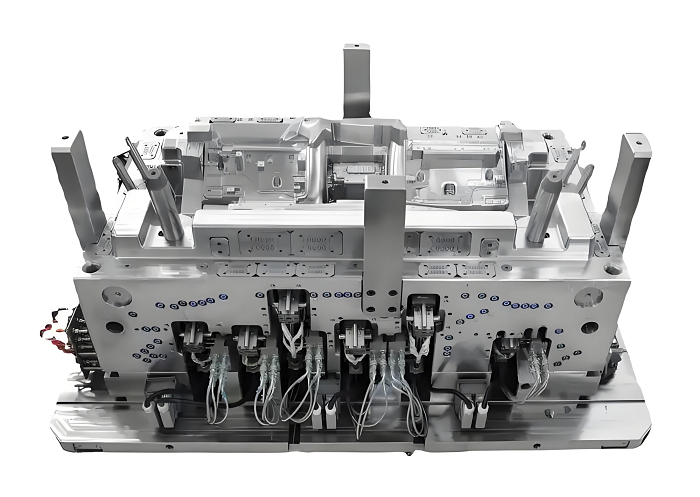

Quick Turn Molding Services Criteria Table

| Guidance | Oover Demolding for standar Mold |  |

||||||

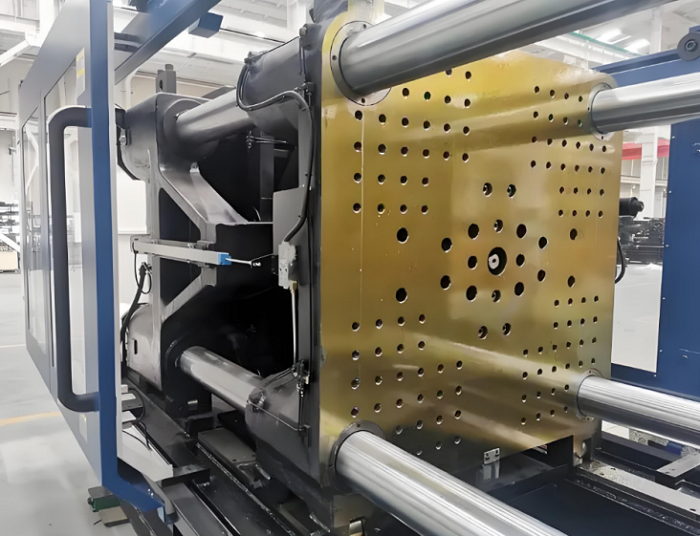

| Tooling | Steel mold | |||||||

| Mold Shot Life | 100000K | |||||||

| Size Limitations | Max XYZ of 2800″x1800″x1000MM | |||||||

| Mold Finishes | 8 Standard finishes (SPI-A2, A3, B2, B3, light or heavy textured) | |||||||

| Material Selection | ABS+PC, PC PMMA, PA, POM, TPE. PP. PA+30%GF. TPU. RUBBER. PBT+30%GF PPS/ PEEK/ PETG/ PA12/ POM-ESD etc. This technique also offers the possibility of plastic over molding (e.g., shore on ABS), over molding of | |||||||

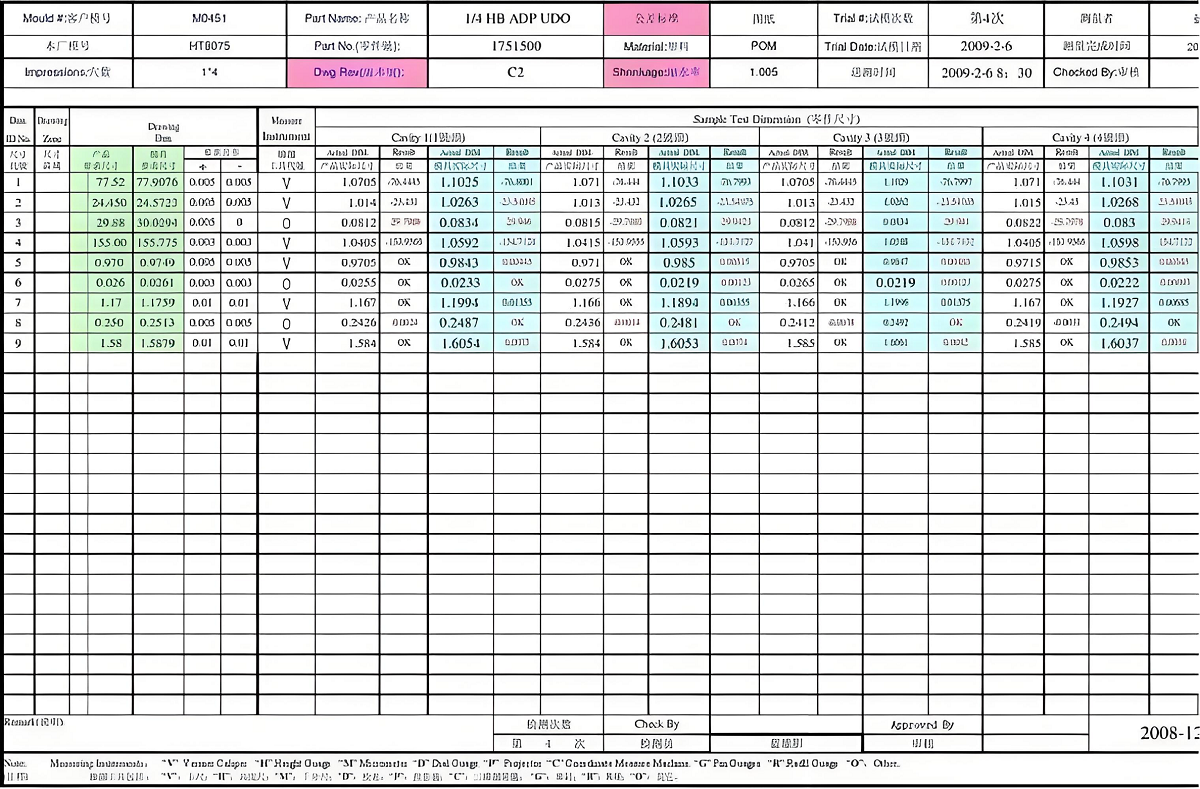

| Inspection Options | Standard/Precision XYZ Dimension Report | |||||||

| Typical Quote Response Time * | Same day, in as little as 2 hours | |||||||

| Part Lead Times | Fast as 30 business days | |||||||

Production Parts Case

|

|

|

|

Why Choose Molding? Rapid tooling’s increasing rate ofadoption is due to its many benefits.

|

Mold Customization Thorough Design and Functionality Testing Faster Time to Market Increased ROI |

|

Need as few as 100 or more than 100,000 injection molded parts? Injection mold tooling is a cost-effective solution for your product development process.

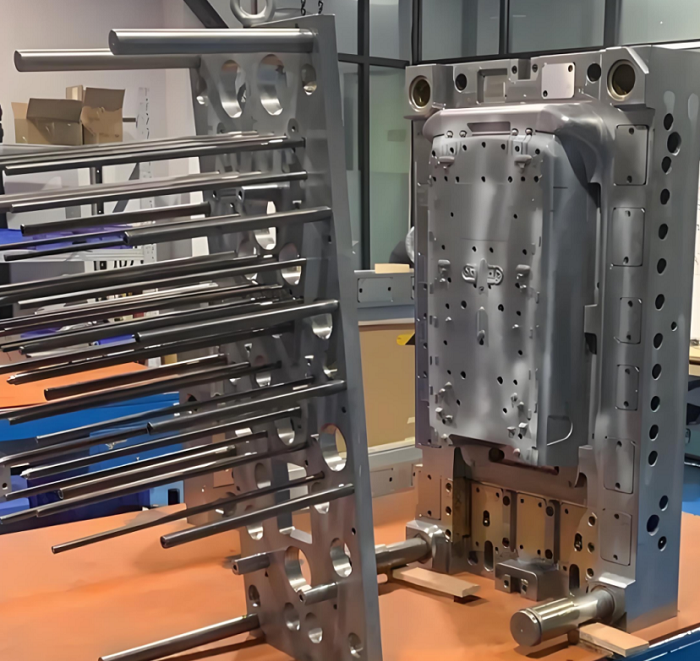

| Optimized Design for Manufacturability (DFM) We incorporate design for manufacturability (DFM) into every aspect of the injection molding process, from part design to injection mold tooling, materials selection, and machining process. No need to wait until production to reveal issues with the design. Our optimized design for manufacturability ensures cost-effective tooling and molding of parts to scale. |

|

| Choose the Right Material of Mold Tools The right material for mold tools will involve considerations such as intended use, volume requirements, design complexity, and mold structure. Not sure which tooling materials to choose? such as intended use, volume requirements, design complexity, best rapid tooling solution for your product needs.We can make rapid mold tools from Aluminum 7075, P20, and NAK80semi-hardened steels and H13 fully-hardened steel. In addition, we also offer standard SPI finishes, EDM texturing, and a range of etched textures including Mold-Tech® MT series and VDI® 3400 series. |

|

| In order to fully satisfy the need for rapid production and low-cost reduction, normally we utilize the Master Unit Die Quick-Change (MUD) System which is proven to save rapid tooling process time and reduce costs. Even more importantly, engineering changes involve only the MUD mold insert, not an entire standard mold base. You can also group several similar parts together on what is known as a family tool for greater savings. In addition, manual or semi-automatic inserts are also often used in rapid mold tooling. |  |

Quality Assurance

Quality Assurance With more than 20 years of manufacturing and processing experience, we already have a complete production and processing process and quality control system, and carry out strict inspections on materials, processing, finished products, shipments and other links to ensure product quality and on-time delivery. The company has passed a number of quality management system certifications, and has been committed to providing customers with efficient and high-quality products and services.

Why Choose Trendy

• We have a fast response rate. Within moments of receiving an email, we start to work, and quotations are sent within 24 hours.

• We have our own design and development team.

• We have a strong quality control system to ensure the best quality products.

• We offer competitive prices and can beat our competitors.

• We send samples asap, and all samples have gone thru quality inspection.

• We provide OEM/ODM services for all kinds of customers.

• We deliver goods on time and communicate transparently with our customers during shipping.

• We take strong pride in the fact that at least 96% of our customer have been with us since we started

• We have mangment team in europen and supply 3rd party services.

Hot Tags: mold sevices, China, manufacturers, factory, customized, wholesale, buy