+86-13077884120

+86-13077884120 +86-13266789839

+86-13266789839

MFG@trendy-sz.com.cn

MFG@trendy-sz.com.cn 86+13077884120

86+13077884120 gxm1235201

gxm1235201 1796474535

1796474535

PU Vacuume Mold

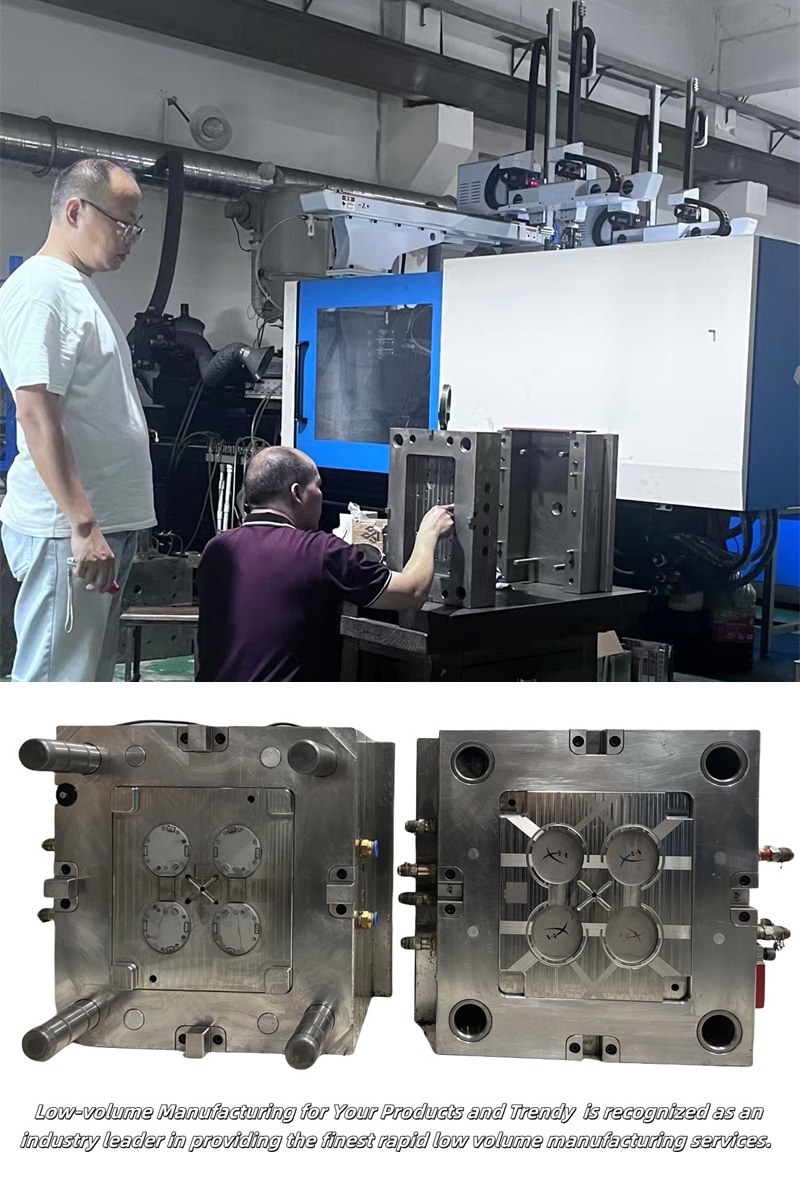

low volume producation One-stop Tooling Solutions Cost-effective and Fast Turnaround Free DFM for Excellent Results)Rapid Tooling Services Low-volume Manufacturing for Your Products Quality Prototyping Manufacturer and Beyond 100 to 10,000+…

low volume producation One-stop Tooling Solutions Cost-effective and Fast Turnaround

Free DFM for Excellent Results)Rapid Tooling Services

Low-volume Manufacturing for Your Products

Quality Prototyping Manufacturer and Beyond 100 to 10,000+ Parts Fast Delivery

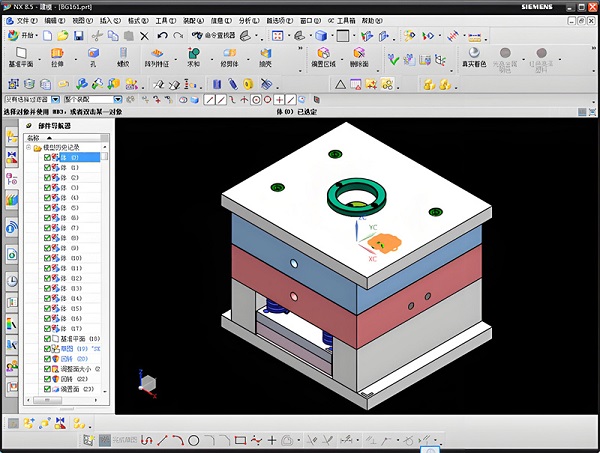

What Is Rapid Tooling?

Rapid tooling is often referred to as prototype tooling, bridge tooling, or soft tooling. Rapid tooling is a crucial step on the path to production. It involves the manufacture of tools used to create products, such as rapid injection molds, rapid die cast molds, sheet metal prototype molds, quick and easy jigs and fixtures, and other custom parts.

Therefore, creating rapid tooling to conduct trial production of hundreds or even thousands of parts before mass production is a very useful process for design optimization, functional testing, or pre-production verification.

Get high-quality rapid tooling solutions for your prototypes and low-volume productions. TRENDY rapid prototype combines engineering capabilities with advanced technology to quickly create injection mold tooling at competitive prices.

low volume producation Available at Trendy

Low volume production is considered to be a specialized service because most manufacturers don’t want to do it. Their assembly lines and supply chains are optimized for large production volumes that leverage economies of scale. There is nothing wrong with that approach, because it’s the best way to ensure the lowest cost per piece. However, it usually requires large minimum order volumes and a commitment to expensive tooling.

But what is a product developer to do if you want to start off with product volumes on the low end, from one part to one thousand? That’s where Star Rapid can help.

What We can provide range material at Trendy.

1. Vacuum casting (MOQ:10-100pcs)

Also known as urethane casting or silicone molding is a rapid prototyping technology allowing the duplication of several tens (1 to 100+) of rigid or flexible plastic parts, using a silicone mold (hence the alternative name of silicone molding). This vacuum molding process is very flexible because it allows to obtain functional parts in good material, with complex shapes (with presence of undercuts), small and large sizes (up to 1.5m). This is done in a short time and without investing in steel tools.

The materials used in vacuum casting are polyurethanes simulating a wide range of materials such as ABS, PMMA, PC, PA, POM, TPE. PP. PA+30%GF etc. This technique also offers the possibility of plastic over molding (e.g., shore on ABS), over molding of inserts and a wide choice of finishes. The physical, mechanical, thermal and aesthetic qualities of the parts created are very similar to those of serial injection parts.

| Rapi Silicon Quick Turn Molding Services Criteria Table | |

| Guidance | Quick Turn Molding for silicon mold |

| Tooling | Prototype grade siicon molds |

| Mold Shot Life | Up 10 to 200 shots |

| Size Limitations | Max XYZ of 1600″x1500″x850MM |

| Mold Finishes | 8 Standard finishes (SPI-A2, A3, B2, B3, light or heavy textured) |

| Material Selection | ABS, PC PMMA, PA, POM, TPE. PP. PA+30%GF. TPU. RUBBER. PBT+30%GF etc. This technique also offers the possibility of plastic over molding (e.g., shore on ABS), over molding of |

| Inspection Options | Standard XYZ Dimension Report |

| Typical Quote Response Time * | Same day, in as little as 2 hours |

| Part Lead Times | Fast as 8 business days |

Production Parts Case

|

|

2. Aluminum tooling support MOQ300-500PCS — Save the mould material cost

Aluminum Mold Tooling – Receive Plastic Parts In 2 Weeks Or Less

High-performance aluminum alloys offer fast and efficient machinability and better thermal conductivity, which helps build molds faster and at a lower cost. More than just a bridge for prototyping or accelerating product launches, aluminum molds are a successful alternative to steel molds that will continue to drive and influence the future of the plastics industry.

This is the ideal choice for prototype injection molding because it is a cost-effective means of producing injection molded parts. Using aluminum ensures dimensional stability in the mold tooling, significantly reducing waste production and part deformation during production. Aluminum molds are also easier to cut, thereby reducing tooling costs by up to 25%. Using aluminum molds also reduces cycle times by 30-40%. All of these combine to ensure faster turnarounds.

|

|

|

Quick Turn Molding Order Criteria

With our quick turn molding service, our goal is to ensure we achieve the best possible turnaround times with as few limitations as possible. That said, there are some considerations when choosing this service to ensure it is suitable for your project. The table below shows our quick turn service offerings and order criteria. For projects requiring fewer limitations and greater customization, visit our plastic injection molding page to see our extensive molding services.

| Rapid Aluminum Quick Turn Molding Services Criteria Table | |||||||

| Guidance | Quick Turn Molding | ||||||

| Tooling | Prototype grade aluminum molds | ||||||

| Mold Shot Life | Up to 2,500 shots | ||||||

| Size Limitations | Max XYZ of 1300″x1200″x800MM | ||||||

| Mold Finishes | 6 Standard finishes (SPI-A2, A3, B2, B3, light or heavy textured) | ||||||

| Material Selection | Limited to 25 families of materials, or customer supplied | ||||||

| Inspection Options | Standard XYZ Dimension Report | ||||||

| Typical Quote Response Time * | Same day, in as little as 2 hours | ||||||

| Part Lead Times | Fast as 10 business days | ||||||

| Supply material including | ABS/ Acetal/ Delrin/ HDPE/ LDPE/ Nylon/ PEEK/ PC/ ABS/ PC/ PET/ PETG/ PMMA (Acrylic)/ Polycarbonate/ PPA/ PPE/ PS/ PSU/ Standard silicone/ Fluorosilicone (fuel and oil resistant) Medical-grade silicone/ Optical-grade silicone |

||||||

Production Parts Case

|

|

|

Why Choose Rapid Molding? Rapid tooling’s increasing rate ofadoption is due to its many benefits.

| Reduced Your Cost of Piece-Part

Low-volume manufacturing avoids the cost issues of production and maintains high quality always. |

|

| Advanced Technology and Equipment

Trendy provides in-house technology and equipment. We will complete your parts under strict quality inspection. |

|

| Inspection Reporting and Certifications

Get added quality assurance from ISO 2768 Medium, ISO 9001 certification. |

|

| DFM (Design for Manufacturing)

We provide one-stop design for manufacturing support to our clients. |

|

| European marketing colleagues can provide 24-hour after-sales service and technical support |

Hot Tags: pu vacuume mold, China, manufacturers, factory, customized, wholesale, buy