+86-13077884120

+86-13077884120 +86-13266789839

+86-13266789839

MFG@trendy-sz.com.cn

MFG@trendy-sz.com.cn 86+13077884120

86+13077884120 gxm1235201

gxm1235201 1796474535

1796474535

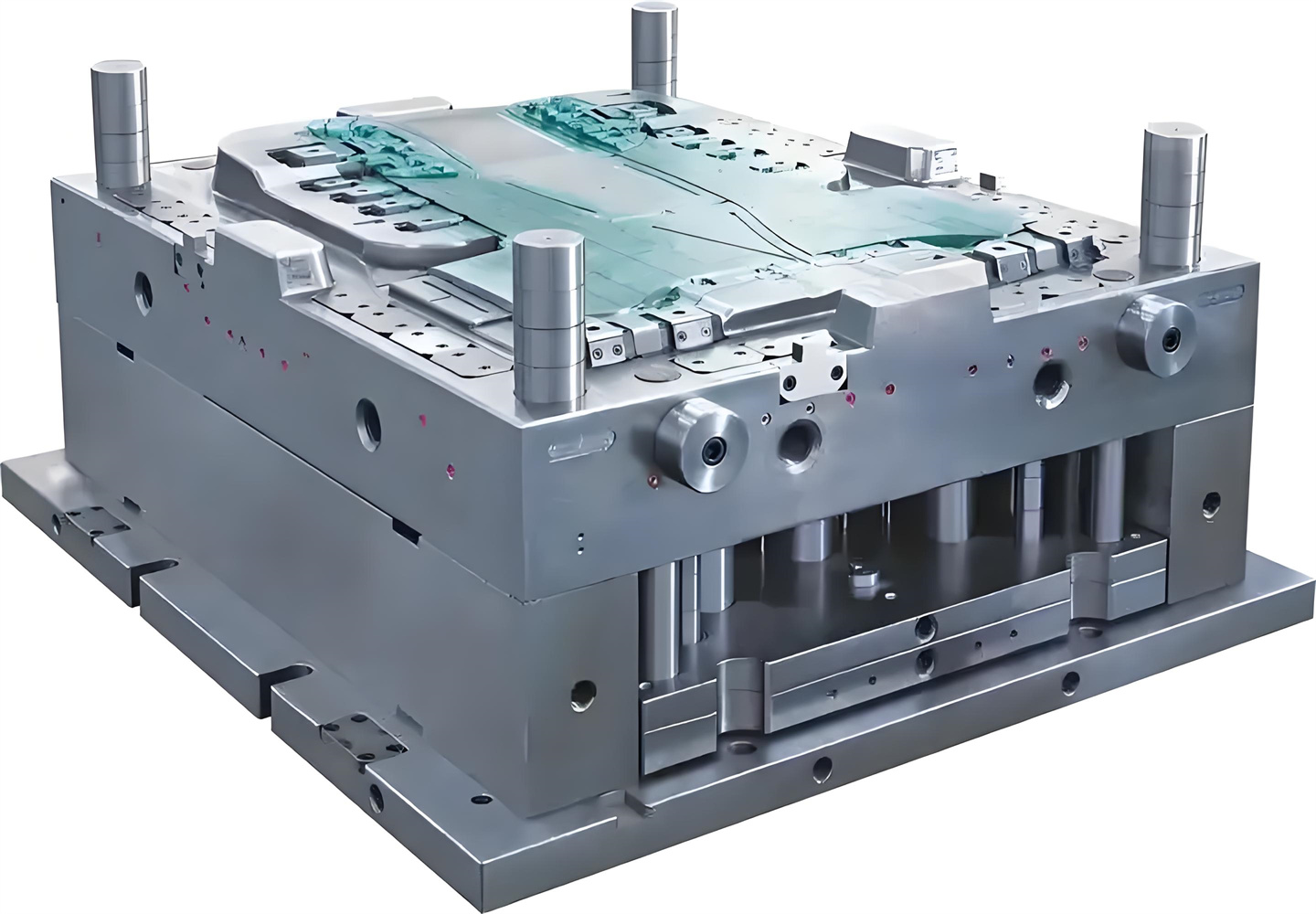

How to choose a suitable mold material with Four characteristics of precision molds

Date:Nov 22,2024

According to the customer’s needs, we will discuss the required raw materials, the required masterbatch, the required mold size, the required molding machine size, cycle time estimation, production time calculation, we also provide customers with parts design services, mold engineering services, mass production arrangements, post-assembly services or post-processing services.

How to choose a suitable mold material

Steel Mold:

Many steel molds are designed to process well over a million parts during their lifetime. For lower volumes, pre-hardened steel molds provide a less wear-resistant and less expensive option.

Aluminum Mold:

The cost of aluminum mold is relatively low, it can economically produce tens of thousands to hundreds of thousands of parts when designed and built using computer numerical control (CNC) machines or Electrical Discharge Machining (EDM) processes. But they typically are ill-suited for high-volume production or parts with narrow dimensional tolerances.

FAQ

1.Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 15 years of rich experience, covering 5000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2.How can you keep your promise about quality?

We have an independent quality department to check every step by IQC, IPQC, OQC.If there are any defective items we willl take corrective action to ensure the elimination of the root cause of defects. When you get the goods and find there is a defect after check. We promise to accept your asked return at our cost or provide replacement free.

3.Is possible to return the money if the quality is not good?

This has never been occured right now, as we treat the quality as our key of development. Quality and service is everything for us.

4.Can Trendy make design drawings for me?

We don’t provide design services. You are responsible for submitting 2D and 3D CAD drawings, and we can then provide a Design for Mant facturing review upon receiving your order.

5.How do I know my design will be kept confidential?

We of coursewil sign and adhere to any non-disclosure or confidentiality agreement. We also have a strict policy within our factory that no photographs are ever lwed of a customers product without express permission. Ultimately we rely on our reputation of working with hundreds ofthousands of unique designs over many years and never allowing any proprietary information to be disclosed to a third party.

1. Abrasion resistance

When the blank is plastically deformed and rotated in the injection mold concave mold, it circulates and rolls along the surface of the mold cavity, causing fierce friction between the surface of the mold cavity and the blank, and then causing the abrasive to be invalid due to damage. Therefore, the corrosion resistance of the material is the most basic of the mold. One of the most important features.

Strength is the primary factor that jeopardizes wear resistance. In general, the higher the strength of the mold parts, the smaller the wear rate, and the higher the wear resistance. In addition, the wear resistance is also related to the type of cementite in the data. Total. Shape. Dimensions and all over the relevant.

2. Strong ductility

Most of the operating standards of the mold are very extreme, and some often bear large impact loads, which can lead to brittle breakage. In order to avoid sudden brittle fracture of mold parts during work, high-precision hardware molds should have high hardness and ductility.

The key to the ductility of modular beak lies in the carbon content of the raw material. Grain size and structure – precision mold manufacturing.

3. Fatigue cracking characteristics

In the process of mold work, under the action of cyclic pressure for a long time, it usually causes fatigue and rupture. Its type has small kinetic energy repeatedly impacting tired ruptures. Lashen is tired and broken, touches tired, broken, and bent and tired.

The key to the fatigue cracking characteristics of the mold is its compressive strength. Ductility. Strength and the composition of the ginseng in its raw materials.

4. High temperature characteristics

When the operating temperature of the mold is high, the strength and hardness will be reduced, resulting in the initial damage of the mold or plastic deformation and ineffective. Therefore, precision hardware mold steel should have high anti-quenching reliability to ensure that the mold has high strength and compressive strength at ambient temperature.