+86-13077884120

+86-13077884120 +86-13266789839

+86-13266789839

MFG@trendy-sz.com.cn

MFG@trendy-sz.com.cn 86+13077884120

86+13077884120 gxm1235201

gxm1235201 1796474535

1796474535

Rapid Injection Molding Materials Can Supply

Date:Feb 28,2025

Rapid Injection Molding tolerance with costs manufacturing advantge ?

Generally speaking, the plastics which can be used for production injection Molding , they can be molded by rapid molding as well. Here are the most commonly molded plastics. If the material is not listed, please contact our team for more information.

Besides of regular production molding, we have over 10 injection molding machines ready for prototype or small quantities molding.the molds will be loaded to the machines right away without delay.

FAQ

-

Why should I use rapid tooling?

Rapid tooling is a fast and cost-efficient way to create a few prototypes in a selected material for function and aspect testing, as well as for low-volume manufacturing to test out the market.

-

How fast can I get the moldings?

This depends on the size and geometry of the parts. For a common open and shut mold with regular size part such as 300 x 300 x 50 mm, fabrication of tools and moldings can be done within 10 days.

-

What materials can I choose from with rapid tooling?

There is no limit to material choice. Any plastics available for mass production, including common silicone and rubber materials, can also be used with the rapid tooling process.

-

What is the quality level of rapid tooling?

Moldings from rapid tooling are end-use-parts quality. They are very close to mass production parts.

-

How many moldings can I get from rapid tooling?

Normally, aluminum molds are good enough for +/- 1,000 shots, while Steel P20 molds can last for +/- 10,000

Tolerances of Rapid Mold Injection Molding

Dimensional Tolerance: Generally

- it ranges from ±0.1mm to ±0.5mm, which depends on the complexity and precision requirements of the product. For example, for simple flat parts, the tolerance can be controlled within ±0.1mm; while for complex three-dimensional structural parts, the tolerance may be relaxed to ±0.5mm.

Shape Tolerance: It includes straightness

- flatness, roundness, etc. The straightness and flatness tolerance usually ranges from ±0.05mm to ±0.2mm, and the roundness tolerance ranges from ±0.02mm to ±0.1mm.

Position Tolerance: Such as parallelism

- perpendicularity, coaxiality, etc. The parallelism and perpendicularity tolerance generally range from ±0.05mm to ±0.3mm, and the coaxiality tolerance ranges from ±0.05mm to ±0.2mm.

Advantages of Rapid Mold Injection Molding

Rapid Prototyping:

- It can manufacture molds and carry out injection molding production in a relatively short time. Compared with traditional mold manufacturing, it can greatly shorten the product development cycle and accelerate the product launch speed.

Lower Cost

- The manufacturing technology and materials used in rapid mold injection molding are relatively low in cost. Especially for small-batch production, it can effectively reduce the production cost.

High Flexibility

- The mold can be quickly modified according to changes in product design, adapting to the production needs of different products. It has great advantages for personalized customization and rapid iteration of products.

Higher Precision:

- Although the tolerance range varies depending on the product, generally, it can meet the requirements of most products with medium precision, ensuring the stability of product quality.

Good Repeatability

- It can ensure that the size and quality of products have high consistency during multiple injection molding processes, which is beneficial to large-scale production.

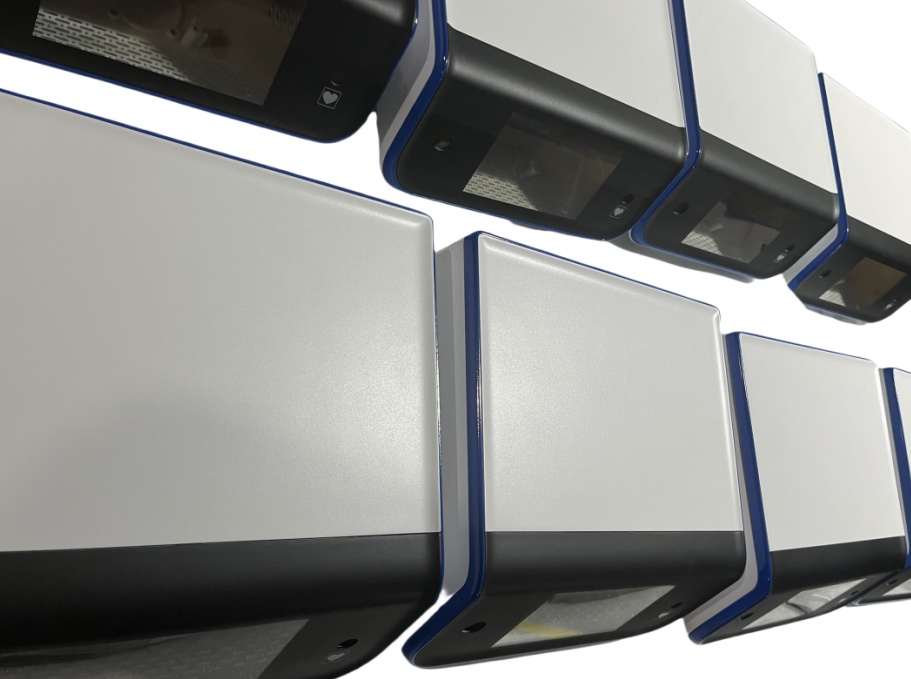

Product Show