+86-13077884120

+86-13077884120 +86-13266789839

+86-13266789839

MFG@trendy-sz.com.cn

MFG@trendy-sz.com.cn 86+13077884120

86+13077884120 gxm1235201

gxm1235201 1796474535

1796474535

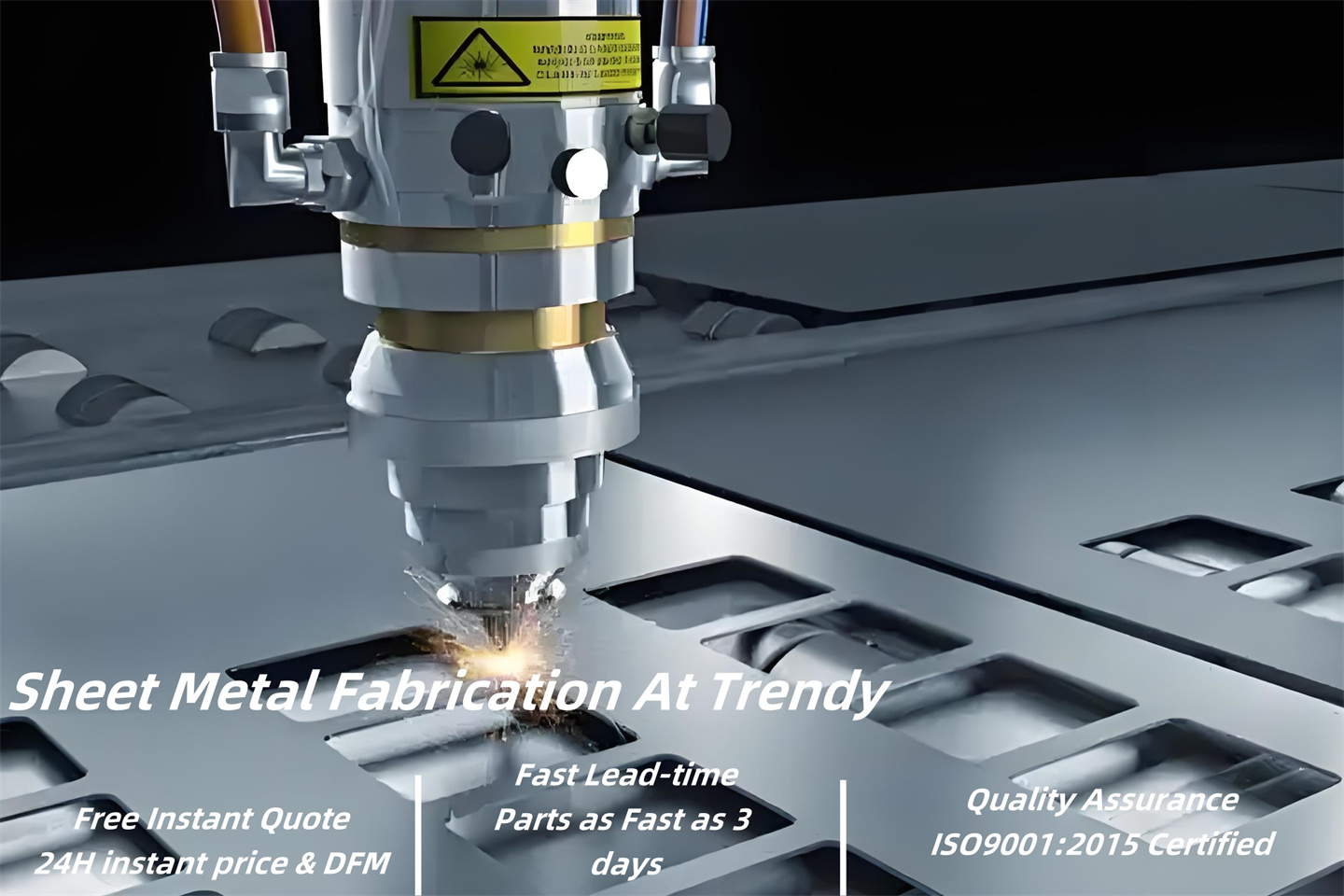

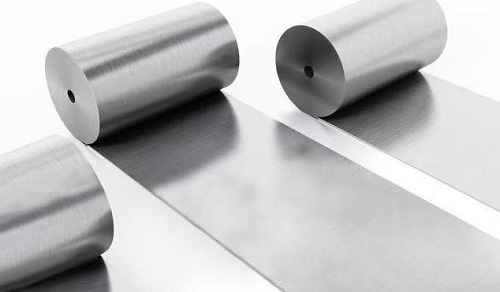

Sheet sheet fabrication

Sheet Metal Fabriaction Sheet Metal Stamping Process There are basically only three components to sheet metal stamping—the sheet metal, die, and press machine—but any single part can require multiple…

Sheet Metal Fabriaction

Sheet Metal Stamping Process

There are basically only three components to sheet metal stamping—the sheet metal, die, and press machine—but any single part can require multiple steps to arrive at its final form. The following guide explains a few common processes that might occur during metal stamping.

• Forming: Forming describes the process of transforming the flat metal into another shape by applying force. It is accomplished in one of several ways, depending on the design specifications for the part. With a series of operations, the metal can be altered from a relatively simple shape into a complex one.

• Blanking: Blanking is the most basic technique and initiates when the sheet or blank is fed into the press where the die cuts out the desired shape. The resulting piece is called a blank. The blank may be the desired part, also known as a fully finished blank, or it may continue to the subsequent step of forming.

• Drawing: Drawing is a more complicated operation and is how vessels or deep depressions are formed. Tension is used to carefully draw the material into a cavity to change its shape. Though the material might stretch while it’s drawn, technicians try to avoid stretching as much as possible to keep the material intact. Sinks, cooking equipment, and oil pans for vehicles are usually made with drawing.

• Piercing: Piercing is almost the opposite of blanking, but instead of saving the blanks, technicians use the material around the outside of the punched area. As an example, think of cutting biscuits from a rolled-out circle of dough. During blanking, the biscuits are saved; during piercing, on the other hand, the biscuits are discarded, and the hole-riddled remains are the desired outcome.

|

|

|

|

Achieve Your Goals with Trendy Precision

|

Trendy Precision provides comprehensive one-stop precision sheet metal fabrication services to meet your various needs.

We have advanced equipment and experienced teams to provide you with high-quality and efficient processing services. |

Gallery of Sheet Metal Fabrication

Whether you need complex mechanical components or simple metal structures, we provide fully customized solutions

|

|

|

|

Precision Sheet Metal Fabrication: Engineering Your Success

In the realm of industrial manufacturing, precision sheet metal fabrication stands as a cornerstone of innovation and efficiency. At Trendy Precision Metal Fabrication, we merge the art of craftsmanship with the precision of modern technology to deliver products that propel your projects to new heights.

Tailored Solutions for Diverse Industries

Our commitment to excellence is reflected in our bespoke services. We cater to a wide array of industries, including aerospace, automotive, and medical devices. By offering customized solutions, we ensure that every component we produce not only meets but exceeds your exact specifications.

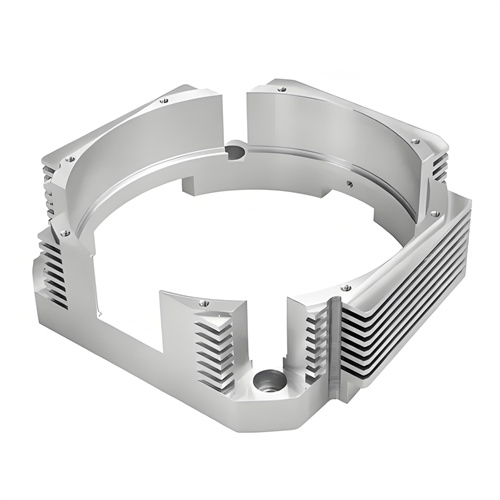

Material Mastery: From Stainless Steel to Titanium

The choice of material is pivotal in metal fabrication. Our expertise encompasses a vast selection of metals, ensuring the perfect match for your application. Our inventory includes:

Stainless Steel: Renowned for its strength and corrosion resistance.

Aluminum: Celebrated for its lightweight and versatility.

Copper: Valued for its electrical conductivity.

Titanium: Sought after for its exceptional durability.

Quality Assurance: Certified Excellence

Trendy Precision Metal Fabrication is synonymous with quality. Our processes are rigorously monitored to comply with international standards, including AS9100D and ISO 9001:2015 certifications. We don’t just aim to meet your expectations; we aim to redefine them.

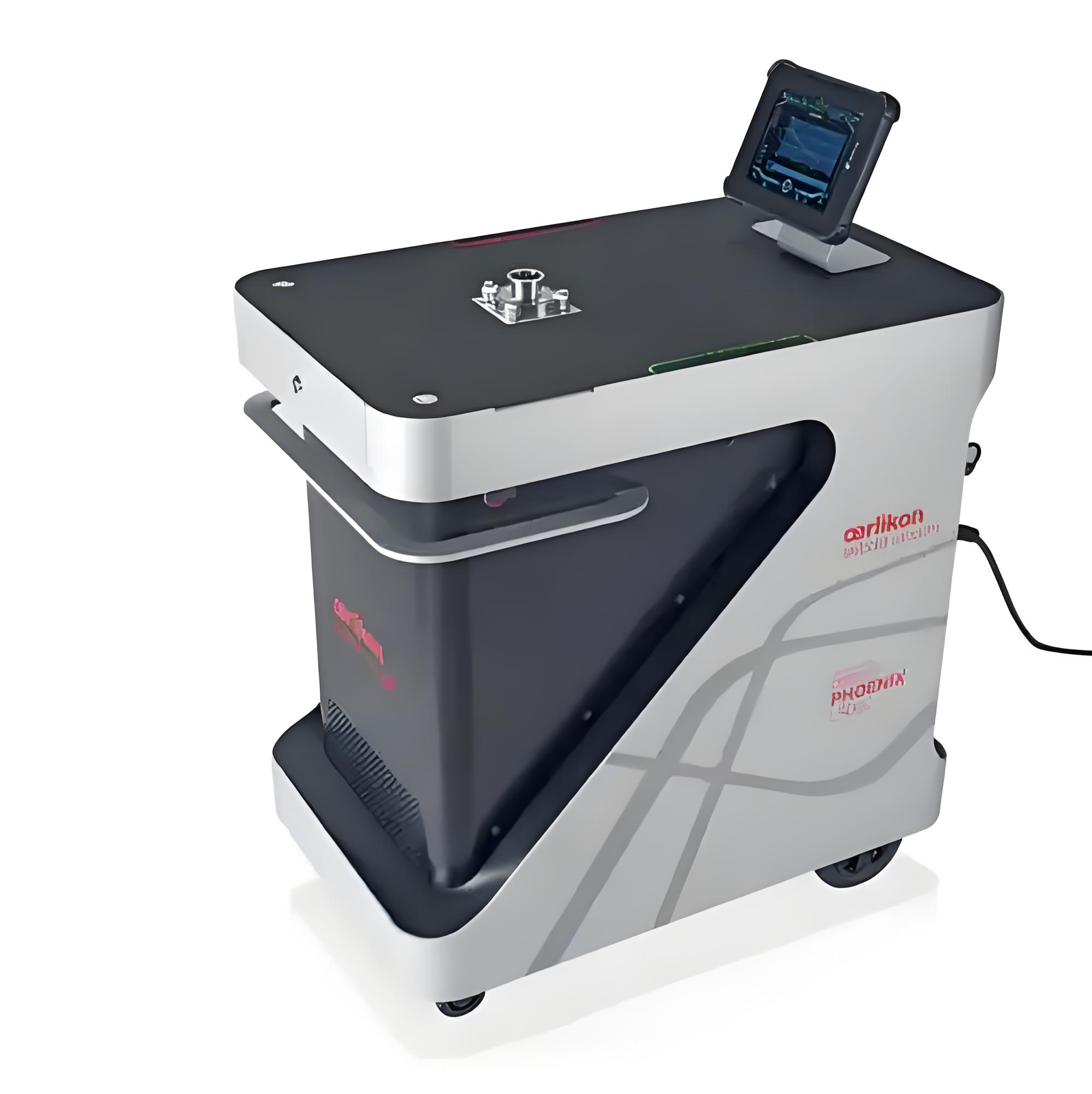

Cutting-Edge Technology for Unmatched Precision

Our state-of-the-art facility boasts an arsenal of advanced machinery, enabling us to execute complex designs with unparalleled accuracy. Our technological suite includes laser cutters, CNC bending machines, and robotic welding stations, all operated by our skilled technicians.

Accelerating Innovation: Rapid Prototyping and Small Batch Production

In today’s fast-paced market, agility is key. Our rapid prototyping and small batch production capabilities allow you to iterate quickly and accelerate your time-to-market. We help turn your concepts into reality, keeping you ahead of the competition.

Sheet Metal Fabrication Capabilities

Our standard tolerances for custom CNC machining of metals is DIN-2768-1-m and for plastics is DIN-2768-1-c. Tolerances are greatly affected by part geometry and type of material. For case-by-case studies, please contact us with email for details.

| Feature | Trendy production with Description |

| Blank Size | 10’ x 20’ (3.05 m x 6.10 m). We accommodate larger part volumes upon request. |

| Standard Lead Time | 4-5business days |

| Sheet Thickness | 0.024” – 0.250” typical. We accommodate thicker or thinner gauges upon request. |

| General Tolerances | For single planes or flat parts, +/- 0.010” on edge to edge, edge to hole, and hole to hole features; +/- 0.010” on bend to edge/hole features. For multi-planed bent parts, +/- 0.030” for hole to hole/edge, edge to edge, and over-formed parts; +/- 1 degree for bend angles. |

| Braking (Hydraulic) | 10’ length, fingers from 3” – 6” |

| Braking (Magnetic) | 6 tons of magnetic pull across the entire beam, 5/8″ minimum reverse bend |

| Punching | 2″ diameter hole capacity, or larger upon request |

| Welding | Welded edges and seams, weldments, and assemblies |

Why you choose Trendy Precision

Trendy Precision is your premier cnc turning company for precision CNC turning services, delivering more than just quality products.

| Tight Tolerance

Parts have a tight tolerance of ±0.02mm, according to DIN-2768 manufacturing standards. |

|

Strong OEM manufacturing capability

With more than 50 cutting-edge CNC lathes and more than 20 years of experience, manufacturing high-quality CNC turned parts with precision and extraordinary appearance to meet all high-volume OEM machining needs |

| 24h Instant Free Quote

Get reliable and detailed CNC turned parts quotes and detailed solutions for your CNC machining orders in as little as 1 hour through our own in-house quotation platform. |

|

Custom Materials & Finishes

50+ Metals and Plastics, 10+ Surface Finishes; Smooth Surface and Strict Tolerance, Custom Material and Surface Treatment. |

| Competitive Price

Fast Quote, Flexible Pricing; High Dimensional Accuracy, High Speed and High Reliability. |

|

High Quality & Lead on Time

Our streamlined production process guarantees high quality and fast and consistent output, and simple orders can be completed as early as 24 hours after placing an order. |

|

|

|

|

1st Approach We Follow

Materials: CNC lathes can process more than 50 models of metal and plastic materials, including:

Metal: Aluminum, magnesium, steel, stainless steel, brass, copper, bronze, titanium

Plastic: Nylon, polycarbonate, ABS, POM, PP, PMMA, PTFE, PEI, PEEK.

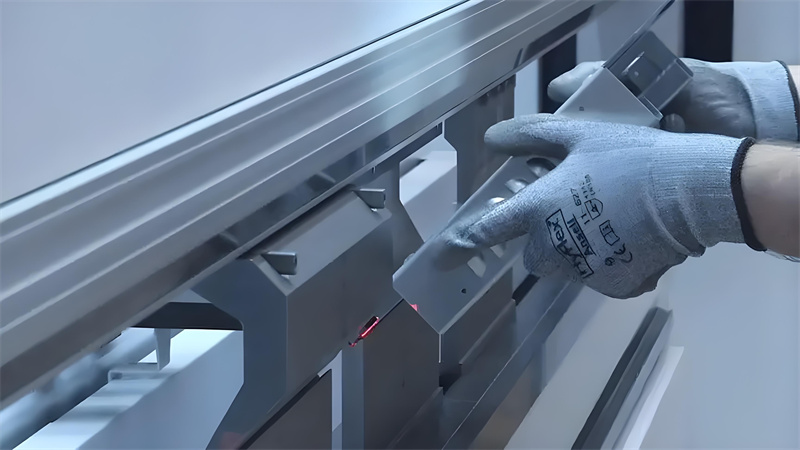

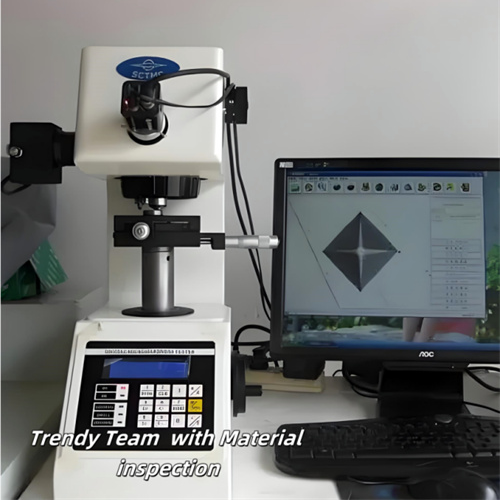

Quality Assurance

With more than 20 years of manufacturing and processing experience, we already have a complete production and processing process and quality control system, and carry out strict inspections on materials, processing, finished products, shipments and other links to ensure product quality and on-time delivery. The company has passed a number of quality management system certifications, and has been committed to providing customers with efficient and high-quality products and services.

Tolerance 600×400

Material inspection

We carry out quality certificate and composition analysis inspection on purchased materials

|

|

|

How to work with us

Upload your 3D Drawing and demand

Quote and Start Manufacturing

Delivery After Inspection

Hot Tags: sheet sheet fabrication, China, manufacturers, factory, customized, wholesale, buy