+86-13077884120

+86-13077884120 +86-13266789839

+86-13266789839

MFG@trendy-sz.com.cn

MFG@trendy-sz.com.cn 86+13077884120

86+13077884120 gxm1235201

gxm1235201 1796474535

1796474535

CNC 5axis Services

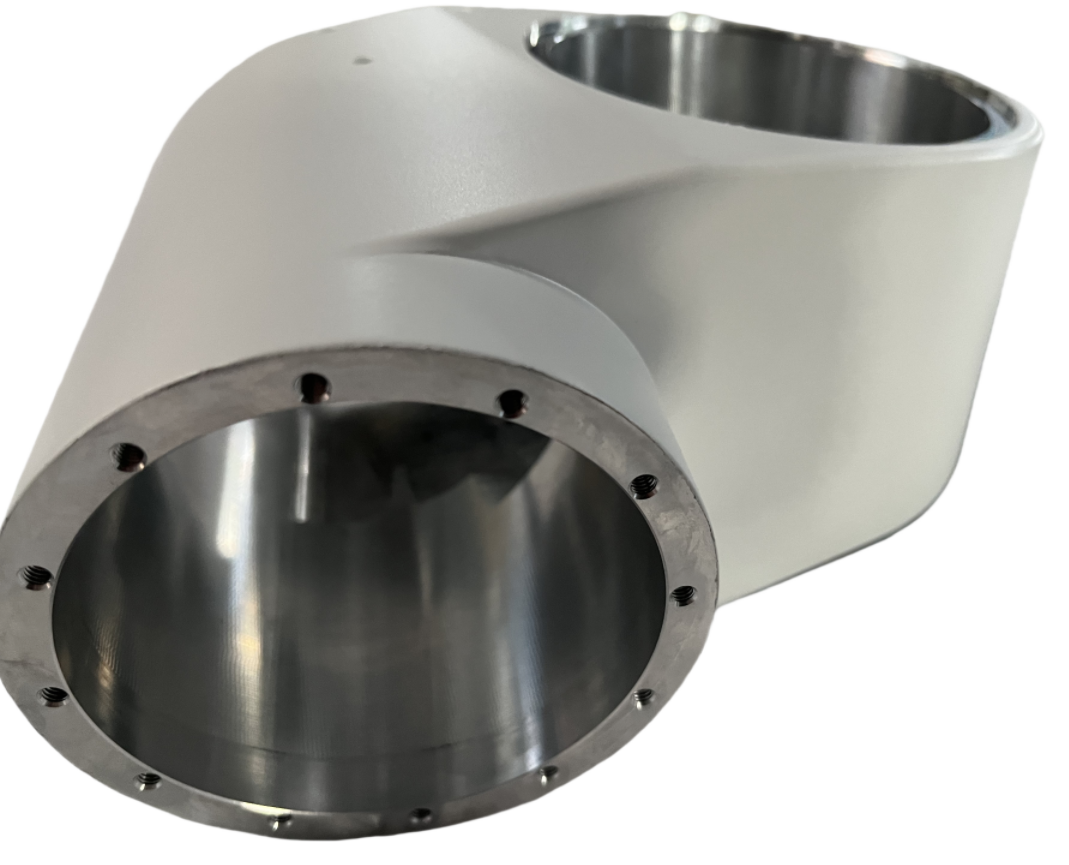

Our 5 Axis CNC Machining Capabilities Looking for 5-axis machining services for your projects? Try Trendy Our 5-axis CNC machines, including HASS and JINGDIAO, allow us to produce high-precision, complex…

| Type | Tolerance |

| Maximum Part Size | 1200 × 800 × 500 mm |

| 15.7 × 11.8 × 7.8 in. | |

| Minimum Part Size | 2 × 2 × 2 mm |

| 0.07 × 0.07 × 0.07 in. | |

| Minimum Feature Size | +/- 0.2mm |

| +/- 0.007in. | |

| Standard Tolerances | Metals: ISO 2768-f |

| Plastics: ISO 2768-m | |

| Linear Dimension | +/- 0.005 mm |

| +/- 0.0002 in. | |

| Hole Diameters | +/- 0.005 mm |

| +/- 0.0002 in. | |

| Shaft Diameters | +/- 0.005 mm |

| +/- 0.0002 in. | |

| Edge Condition | Sharp edges are broken and deburred by default |

| Threads and Tapped Holes | Trendy can accommodate any standard thread size. We can also machine custom threads. |

| Lead Time | 3 -5 Business Days

|

1. High Cost

The cost of acquiring a 5-axis CNC machine is quite higher than that needed to purchase a 3-axis machine. The same goes for the software needed for operating this machine. Also, maintaining 5-axis CNC machines is more difficult than maintaining CNC machines. Therefore, the cost is one of the major drawbacks of using 5-axis CNC machines for machining.

2. Programming Complexity

The programming needed for 3-axis machines differs from that required by 5-axis machines. This is primarily due to the addition of two rotational motions, which complicates the trajectory of the synthetic motion formed.

For instance, programming the 5-axis would have to consider each axis’s respective motion to avoid collision and interference. Also, achieving better surface quality and precision requires more complex programming.

3. Requires a High Level of Operator Skill

5-axis CNC machining involves the use of advanced technology. Therefore, a highly skilled technical operator is necessary to get the best out of the machine. However, employing a highly skilled operator also increases labor costs.

Gallery Of 5 Axis Machining Parts

Hot Tags: CNC 5axis Services, China, manufacturers, factory, customized, wholesale, buy