+86-13077884120

+86-13077884120 +86-13266789839

+86-13266789839

MFG@trendy-sz.com.cn

MFG@trendy-sz.com.cn 86+13077884120

86+13077884120 gxm1235201

gxm1235201 1796474535

1796474535

CNC turning Lathe Services

Achieve Your Goals with Trendy Precision Trendy Precision’s CNC Turning Lathe: Redefining the Standards of Precision Machining In the realm of high – end manufacturing, Tianyituo Precision Technology’s CNC…

Achieve Your Goals with Trendy Precision

Trendy Precision’s CNC Turning Lathe: Redefining the Standards of Precision Machining

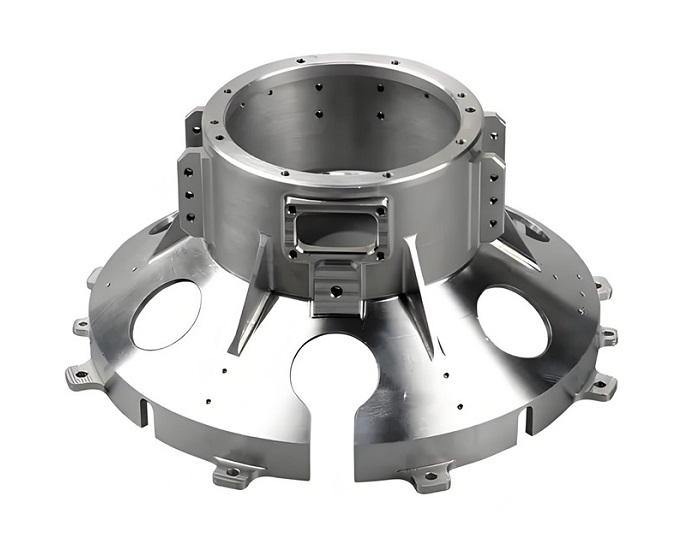

In the realm of high – end manufacturing, Tianyituo Precision Technology’s CNC turning lathes stand out as the ultimate choice for complex and precise parts machining, thanks to their exceptional performance and exquisite craftsmanship.

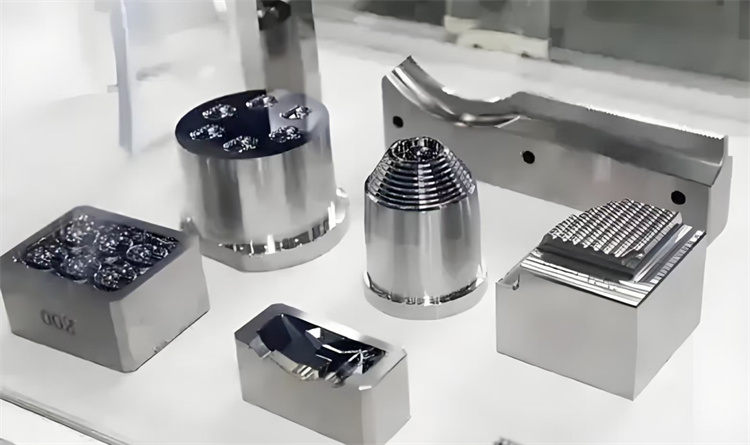

Tianyituo’s CNC turning lathes possess powerful processing capabilities. Whether it is the delicate carving of small – and medium – sized parts or the efficient cutting of large workpieces, they can handle it with ease. Their high – precision spindle systems and advanced servo drive devices ensure that every rotation and every tool feed is accurate. Even the dimensional tolerance requirements in the micron range can be perfectly met.

In terms of surface treatment processes, Tianyituo’s CNC turning lathes truly showcase their ingenuity. Through optimized tool path planning and parameter control, the surface of the processed parts is as smooth as a mirror, with fine textures that resemble silk, greatly enhancing the product’s aesthetics and functionality. Whether it is precision components for the aerospace industry or key components for the automotive industry, Tianyituo’s CNC turning lathes can endow them with outstanding quality.

In addition, our CNC turning lathes support diverse processes, covering internal and external cylindrical machining, conical surface machining, thread cutting, contoured surface machining, etc. Relying on rich programming experience and flexible machining strategies, we can customize personalized solutions according to customer needs.

Tolerance with capcity size

| Type | Tolerance |

| Maximum Part Size | 3000 × 1800 × 850 mm |

| 10.7 × 11.8 × 7.8 MM | |

| Minimum Part Size | 2 × 2 × 2 mm |

| 0.07 × 0.07 × 0.07 in | |

| Minimum Feature Size | +/- 0.2mm |

| +/- 0.007in. | |

| Standard Tolerances | Metals: ISO 2768-f |

| Plastics: ISO 2768-m | |

| Linear Dimension | +/- 0.005 mm |

| +/- 0.0002 in. | |

| Hole Diameters | +/- 0.005 mm |

| +/- 0.0002 in. | |

| Shaft Diameters | +/- 0.005 mm |

| +/- 0.0002 in. | |

| Edge Condition | Sharp edges are broken and deburred by default |

| Threads and Tapped Holes | Trendy can accommodate any standard thread size. We can also machine custom threads. |

| Lead Time | 3 -5 Business Days

|

Trendy Precision is your premier cnc turning company for precision CNC turning services, delivering more than just quality products.

|

|

Trendy with CNC Turned Parts with advantage

| The advantages of CNC turning lathe are particularly well suited to the requirements of low-volume production runs of custom parts. Its accuracy and repeatability, flexible processes, as well as a wide range of material options help bring products to market faster. Whatever you need to custom machined parts or products, our CNC machine shop can offer integrated solutions to help you shorten production time.

Need 50 or 10,000 custom machined parts? We have the capability and experience to provide efficient custom CNC machining services at a reasonable price. |

|

What material we can supply at Trendy?

| Material | Also Known As | Type | Description | colors |

| 1018 Steel | Low Carbon Steel 1018 | metal | General Purpose 1018 steel is the most prominent of the carbon steels. The low carbon content makes this steel ductile and suitable for forming and welding. | |

| 4130 Alloy Steel | Alloy Steel 4130 | metal | Offers great weldability without compromising impact resistance. Often used in gears and fasteners. |

|

| Alloy Steel 4140 | Alloy Steel 4140 | metal | Additional chromium makes this steel corrosion and fracture resistant |

|

| Aluminum 2024-T3 | 2024 Aluminum /AL7075 /2A12/ /T6061 /6063 /Aluminum MIC-6 /Aluminum 7075 T735 |

metal | 2024 Aluminum is used when a high strength-to-weight ratio is required, such as for gears, shafts, and fasteners. It is nonmagnetic and heat treatable Aluminum 6061 is easily machined and lightweight, perfect for prototypes, military, and aerospace applications Commonly used outdoors as architectural trim, railings, and door frames, 6063 aluminum has better machinability than 3003. It is nonmagnetic and heat treatable AL 7075 aluminum for use in structural applications, 7050 is a high-strength material that resists fatigue and stress cracking. 7050 is nonmagnetic and heat treatable MIC6 ALUMINUM: A cast aluminum plate often used for tooling and base plates. AL7075 T735; Harder and higher strength aluminum alloy good for high-stress parts. |

|

| Brass 260 | Easy Forming Brass 260 Machining Brass C360 |

metal | C360: A highly machinable brass. Great for prototyping gears, fittings, valves and screws. Bearing Bronze C932: C260: A highly formidable brass. Great for radiator components and decorative door hardware. |

|

| C932 M07 Brg Brz | C932 M07 Brg Brz Copper 101 |

metal | C932 is the standard bearing bronze for light-duty applications. It is easily machinable and resistant to corrosion Copper 101: Commonly known as Oxygen-Free Copper, this alloy is great for electrical conductivity. |

|

| TCc4tai | TC4TAI /3d PRINTING /CNC | metal | High strength, light. Corrosion resistance, high temperature resistance, biocompatibility, suitable for medical, construction, Marine, oil collection | |

| STEEL | Stainless Steel 416 /304 / 316 /Steel 18-8 /Stainless Steel 420 | metal | 416: Easily machinable but can be heat treated to increase strength and hardness. Low corrosion resistance 304/316l/303L: A highly corrosion-resistant steel popular for medical devices Stainless Steel 18-8: One of the most commonly used stainless steels. Also known as Stainless Steel 304 Stainless Steel 420: Contains more carbon than Stainless 410 to give it increased hardness and strength when heat treated. Offers mild corrosion resistance, high heat resistance, and improved strength. |

|

| mold steel /hanress | Z160CVD12 /SKD11 /SKD6 /S136H /40CMD8 /NAK80 /CR12 /P20 /Q235 /s235JR /65Mn | metal | surface to heat treament. norally to use mold base and insert mold part. or spare parts customized metal |

|

| plstic resin | black ABS /PC /P /POM /PMMA /PBT /PA66+30%GF /PTFE | plastic | it is used for CNC machining. | |

| Additional plstic | Peek /Polypropylene (PP PTFE /)Nylon 6/6 | plastic | pp: Polypropylene has excellent electrical properties and little or no moisture absorption. It carries light loads for a long period in widely varying temperatures. It can be machined into parts requiring chemical or corrosion resistance. PTFE: This material surpasses most plastics when it comes to chemical resistance and performance in extreme temperatures. It resists most solvents and is an excellent electrical insulator peek: Offering excellent tensile strength, PEEK is often used as a lightweight substitute for metal parts in high-temperature, high-stress applications. PEEK resists chemicals, wear, and moisture |

|

| carbon | carbon+30%GF | plastic |

Why You Choose Trendy Precision

| Tight Tolerance Parts have a tight tolerance of ±0.02mm, according to DIN-2768 manufacturing standards. |

|

Strong OEM manufacturing capability With more than 100 cutting-edge CNC lathes and more than 20 years of experience, manufacturing high-quality CNC turned parts with precision and extraordinary appearance to meet all high-volume OEM machining needs |

| 24h Instant Free Quote Get reliable and detailed CNC turned parts quotes and detailed solutions for your CNC machining orders in as little as 1 hour through our own in-house quotation platform. |

|

Custom Materials & Finishes 50+ Metals and Plastics, 10+ Surface Finishes; Smooth Surface and Strict Tolerance, Custom Material and Surface Treatment. |

| Competitive Price Fast Quote, Flexible Pricing; High Dimensional Accuracy, High Speed and High Reliability. |

|

High Quality & Lead on Time Our streamlined production process guarantees high quality and fast and consistent output, and simple orders can be completed as early as 24 hours after placing an orde |

Hot Tags: cnc turning lathe services, China, manufacturers, factory, customized, wholesale, buy